Plywood is an engineered wood product made of thin wood veneer layers glued together. If you’ve ever walked into a timber yard or scrolled through a supplier’s site and felt completely lost in the alphabet soup of A, B, C, and D plywood grades, you’re not alone. Choosing the right plywood comes down to more than just picking the cheapest sheet. The grading system tells you everything you need to know about appearance, performance, and where the sheet belongs: on show, hidden behind a wall, or under your feet.

Let’s break it down so you know exactly what you’re looking at next time you're loading the ute or quoting a job.

What Is Plywood Grading?

Plywood grading is a system used to classify the veneer grade of the face and back layers, essentially, how clean or clear those outer surfaces appear. It also gives you a clue about how well the sheet’s glued together and how it’ll hold up in different conditions (like moisture, for example). Basically, the better the grade, the better it looks, and usually, the higher the cost.

The Main Appearance Grades

Veneer quality is all about how the outer layers of a plywood sheet look and hold up. These layers, called veneers, are graded based on how clean, smooth, and defect-free they are. The better the veneer, the more suitable it is for jobs where the sheet will be seen. Lower grades are fine for structural or utility work where looks don’t matter, but if it’s going on show, you want a high-grade face.

A-Grade Plywood

A-grade veneer faces are top-shelf stuff. It has a clean and smooth surface (S face), sanded, and with no visible knots or defects. Any little flaws have been filled to perfection. You’d use an A-grade plywood where the finish is everything, like kitchen cabinetry, feature walls, or high-end furniture. Great for staining or a clear coat.

B-Grade Plywood

Good quality and reliable, but a bit more forgiving. The surface of a B-grade plywood is sanded and still presentable, but you might spot small knots or repairs up to 30mm. It’ll take paint or stain well and is ideal for building shelves, painted joinery, or internal fit-outs where you want it to look nice but don't need it to be perfect.

C-Grade Plywood

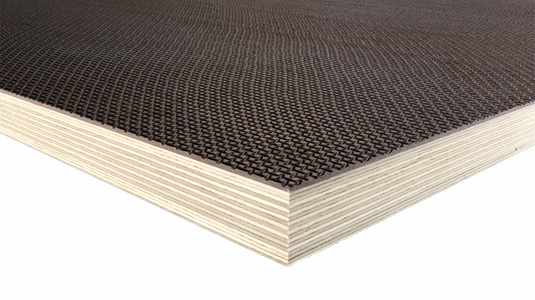

Now we’re getting into utility territory. C-grade plywood isn’t sanded and will show larger knots (up to 50–100mm), splits, and colour variations. Some of the defects may be patched. It's fine for projects that you’re not going to see, but it has to have a solid surface, such as subfloors, roof sheathing, or temporary structures.

D-Grade Plywood

This is as basic as it gets. It's not sanded, nor has it been patched at all, so it's full of visible defects. You’d only use D-grade plywood in places that are hidden, rough, or temporary, including framing, underlay, or anywhere that needs cheap and quick coverage with no visual expectations.

Combined Grades (Face/Back)

Plywood is usually graded with two letters (like AB or CD), where the first letter is the face (the visible side), and the second is the back (the hidden one).

- AA – Premium finish on both sides. Pricey, but pristine.

- AB – High-quality front, decent back. Good for cabinetry and displays.

- BB – Both sides presentable, with minor flaws. Ideal for both faces being semi-visible.

- CD – One side rough but workable, the other very basic. Common in construction.

- CDX – Same as CD, but the "X" means it's bonded with water-resistant glue, so it’s suitable for outdoor or moisture-exposed areas like bracing, hoarding or exterior cladding.

Other Factors That Matter

Grading doesn’t stop at appearance. There are a few other things to check, especially if your sheet's going into wet areas or holding up a load.

Adhesive/Bond Types

The type of glue bonds used tells you where the sheet can safely go. Here are bond types used in plywood manufacture:

Type A Bond:

This is the toughest of the lot. It uses phenol-formaldehyde resin, which is highly water-resistant and built to withstand harsh conditions over the long haul. You'll find Type A bond in exterior plywood, marine ply, and structural plywood sheets designed for bracing, cladding, or anything permanently exposed to the elements. If it’s going outside or needs to handle repeated wetting and drying, this is the bond you want.

Type B Bond:

Not quite as hardcore as Type A, but still a solid performer. Type B plywood uses melamine-fortified urea-formaldehyde glue, which holds up in areas with moderate moisture exposure. It’s common in exterior-grade panels used for things like covered outdoor areas, garages, or utility spaces. Just don’t throw it into constant wet conditions. It’s water-resistant, not waterproof.

Type C/D Bond:

These are strictly for dry, indoor use. They’re bonded with standard urea-formaldehyde glue and aren’t built to handle moisture or humidity. You’ll typically see Type C/D plywood in non-structural applications like interior wall panelling, built-in furniture, or decorative finishes. Affordable and lightweight, but keep them well away from bathrooms, laundries, or anywhere they might get a bit of damp.

Structural vs Non-Structural

Structural ply is made and tested to meet Australian Standards for strength and load-bearing. It’s stamped with AS/NZS 2269 and used in floors, walls, and roofs. Non-structural ply is more for linings, furniture, or decorative work. It looks good, but it isn’t rated for holding up weight.

Species

The timber species used in the veneers affects everything from appearance to strength, influencing the performance and price of the plywood material overall. Birch is dense and great for cabinetry. Radiata pine is light and widely used in structural ply. Hardwood-faced ply is tough and looks good, but expect to pay more.

Choosing Quality Plywood for Your Next Project

Here’s the short version:

- Need it to look good? Go A or B grade.

- Need it cheap and hidden? A C or D grade will do.

- Outside or wet area? Look for Type A bond or CDX-rated sheets.

- Carrying load or structural? Make sure it’s certified structural plywood.

Knowing how to match different grades of plywood to the right task means fewer headaches, a better result, and less waste. Once you understand what those letters mean, it’s a lot easier to walk into a supplier and know exactly what to ask for.

The Power of Knowing Your Plywood

At the end of the day, plywood grading is the key to getting the right sheet for the job. Whether you're building a polished feature wall or knocking up temporary formwork, understanding the right plywood grade helps you avoid surprises, save money, and finish with a better result. Pick the wrong grade, and you’ll spend more time patching, sanding, or replacing than building. Pick the right one, and the job just works.

Purchasing plywood? Chat to the team at DMK Forest Products. We’ll help you get the right grade, in the right spec, for the right price.