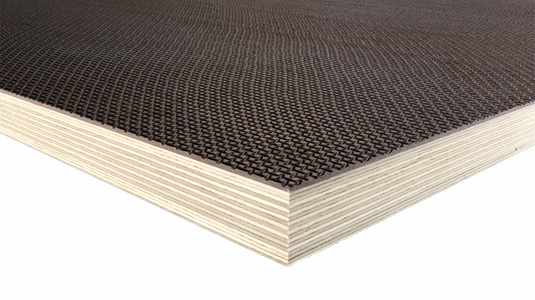

Looking for a flooring material that can withstand the demands of high-traffic environments? Look no further than Hexa Plywood. Part of our full range of WISA Birch Plywood products, Hexa panels feature a durable phenolic resin laminate imprinted with a distinctive hexagonal pattern. The reverse side is coated with phenolic film for added protection.

Ideal for demanding applications like transport vehicles, industrial floors, work platforms, and more, DMK Forest Products‘ Hexa Plywood offers exceptional durability and performance.

General Product Information

Key Features

- Hexagonal Pattern: Provides enhanced grip and slip resistance.

- Phenolic Resin Coating: Ensures durability and weather resistance.

- Moisture Barrier: Protects against moisture penetration.

- Edge Protection: Acrylic-based paint for added durability.

- Customisable: Edge and CNC machining available upon request.

Specifications

- Thicknesses: 9, 12, 15, 18, 21, 24, 27, and 30 mm

- Panel Sizes:

- 1220/1250 x 2440/2500 mm

- 1525 x 2440/2500/3050 mm

- Largest Standard Size: 1525 x 3660 mm

- Size Tolerances: +/- 1 mm for panels under 1000 mm, +/- 2 mm for panels between 1000 and 2000 mm, and +/- 3 mm for panels over 2000 mm.

- Squareness Tolerance: +/- 1 mm / 1000 mm

- Moisture Content: 8-10%

Performance

- Wear Resistance: Average 570 cycles (Taber DIN 53799)

- Rolling Test: 1750 cycles (SS 923502)

- Chemical Resistance: Endures mild alkalis

- Strength Values: As per the Handbook of Finnish Plywood

Recommendations

- Ideal for flooring applications where heavy localised loads are not expected.

- Scarf-jointed one-piece floors provide large, seamless surfaces.

Additional Information

- For more details on installation, maintenance, disposal, and environmental matters, please contact your supplier or UPM.

- UPM reserves the right to amend specifications without notice.

- Any defects not caused by clearly verified production or service faults by the supplier are the responsibility of the user.

Note: The largest scarf-jointed size is 5600 x 1950 mm, and the largest size in grey colour is 5600 x 1800 mm.

Benefits of Hexa Plywood

Discover the exceptional advantages of Hexa Plywood from our WISA Birch Plywood range, a premium flooring material designed to elevate your space. Hexa offers a range of benefits that make it a highly desirable choice for demanding applications.

Durability and Performance

Hexa Plywood is engineered for exceptional durability, featuring a hexagonal pattern and phenolic resin coating that provide superior resistance to wear and tear, slip resistance, and moisture penetration. It resists commonly used household chemicals, making it suitable for various environments and ensuring long lasting performance in even the most demanding applications.

Versatility and Aesthetics

Hexa Plywood's versatility extends to a wide range of applications, making it an ideal choice for flooring in demanding environments such as transport vehicles, industrial floors, work platforms, spectator stands, and terraces. Beyond its functional benefits, Hexa Plywood also adds a touch of aesthetic appeal with its distinctive hexagonal pattern, enhancing the visual interest of any space.

Practicality and Ease of Use

Hexa Plywood offers practical advantages in addition to its durability and aesthetics. Its scarf-jointed one-piece floors provide large, seamless surfaces, minimising the need for seams and joints, creating a more visually appealing and maintenance-friendly floor. Furthermore, Hexa Plywood's durable surface is relatively easy to clean and maintain, making it a practical choice for busy environments.

Environmental Considerations

Hexa Plywood is not only a high-performance flooring material but also an environmentally friendly choice. It is manufactured using sustainable materials and processes, minimising its environmental impact and contributing to a greener future. By choosing Hexa Plywood, you are making a conscious decision to support sustainable practices and reduce your carbon footprint.

Elevate Your Flooring with Hexa Plywood

Hexa Plywood offers a compelling combination of durability, aesthetics, and sustainability. Its exceptional wear resistance, slip resistance, and moisture resistance make it ideal for demanding applications. The distinctive hexagonal pattern adds a touch of style, while its easy maintenance and sustainable production contribute to its appeal.

Ready to experience the Hexa Plywood difference? Contact DMK Forest Products today to learn more about this premium flooring solution and explore our range of other plywood products in stock. Our knowledgeable team is ready to assist you in finding the perfect plywood for your project.