Wisa S/BB Birch E0 Exterior Plywood Group 3 Fire Certified

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 2440 x 1220 | 6.5mm | 5 ply | 4.4 kg m2 | 140 |

| 2440 x 1220 | 9mm | 7 ply | 6.1 kg m2 | 100 |

| 2440 x 1220 | 12mm | 9 ply | 8.2 kg m2 | 75 |

| 2440 x 1220 | 15mm | 11 ply | 10.2 kg m2 | 60 |

| 2440 x 1220 | 18mm | 13 ply | 12.2 kg m2 | 50 |

| 2440 x 1220 | 24mm | 17 ply | 16.3 kg m2 | 35 |

| 2440 x 1220 | 30mm | 21 ply | 20.4 kg m2 | 30 |

This Premium E0 Birch “LONG-GRAIN” Plywood strives for 1 clean face “S” & 1 face with butterfly patches BB. This plywood is multi-layered made up of 1.4mm veneer & minimal

Wisa S/BB Birch E0 Exterior Plywood Maxi Panel Group 3 Fire Certified

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1525 x 3050 | 4mm | 3 ply | 3.0 kg m2 | 100 |

| 1525 x 3050 | 6.5mm | 5 ply | 4.4 kg m2 | 80 |

| 1525 x 3050 | 9mm | 7 ply | 6.1 kg m2 | 60 |

| 1525 x 3050 | 12mm | 9 ply | 8.2 kg m2 | 50 |

| 1525 x 3050 | 12mm | 9 ply | 8.2 kg m2 | 50 |

| 1525 x 3050 | 15mm | 11 ply | 10.2 kg m2 | 40 |

| 1525 x 3050 | 15mm | 11 ply | 10.2 kg m2 | 40 |

| 1525 x 3050 | 18mm | 13 ply | 12.2 kg m2 | 35 |

| 1525 x 3050 | 18mm | 13 ply | 12.2 kg m2 | 35 |

| 1525 x 3050 | 24mm | 17 ply | 16.3 kg m2 | 25 |

| 1525 x 3050 | 30mm | 21 ply | 20.4 kg m2 | 20 |

| 1525 x 3050 | 35mm | 25 ply | 24.2 kg m2 | 15 |

This Premium E0 Birch “CROSS-GRAIN” Plywood strives for 1 clean face “S” & 1 face with butterfly patches BB. This plywood is multi-layered made up of 1.4mm veneer & minimal core voids. Used to manufacture furniture, joinery, wall linings, shop fitouts and many more.

Wisa Twin B/WG Exterior Plywood

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 2440 x 1220 | 5mm | 3 ply | 2.6 kg m2 | 140 |

| 2440 x 1220 | 9mm | 5 ply | 4.5 kg m2 | 100 |

| 2440 x 1220 | 12mm | 5 ply | 6.5 kg m2 | 75 |

| 2440 x 1220 | 15mm | 6 ply | 7.4 kg m2 | 60 |

| 2440 x 1220 | 18mm | 9 ply | 8.9 kg m2 | 50 |

| 2440 x 1220 | 24mm | 8 ply | 11.4 kg m2 | 35 |

| 2440 x 1220 | 30mm | 12 ply | 17. 8 kg m2 | 15 |

| 2440 x 1220 | 36mm | 18 ply | 25.2 kg m2 | 10 |

| 2440 x 1220 | 51mm | 24 ply | 25.3 kg m2 | 10 |

Wisa Twin is a Premium Birch “LONG-GRAIN” Plywood with a Birch face on 1 side where butterfly patches are permitted & has a WG back. In production of 30mm, 36mm & 51mm, a PVA “B bond” glue is used for pressing and is B/B. This plywood is lightweight with Birch faces with a Spruce Pine

Finnish Birch Exterior Craft Ply

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1220 x 1220 | 0.4mm | 3 ply | 0.30 kg m2 | AB/B |

| 1220 x 1220 | 0.6mm | 3 ply | 0.45 kg m2 | AB/B |

| 1220 x 1220 | 0.8mm | 3 ply | 0.60 kg m2 | AB/B |

| 1220 x 1220 | 1.0mm | 3 ply | 0.80 kg m2 | AB/B |

| 1220 x 1220 | 1.5mm | 3 ply | 1.20 kg m2 | AB/B |

| 1220 x 1220 | 2.0mm | 4 ply | 1.60 kg m2 | AB/B |

| 1220 x 1220 | 2.5mm | 5 ply | 2.00 kg m2 | AB/B |

| 1220 x 1220 | 3.0mm | 6 ply | 2.40 kg m2 | AB/B |

| 1220 x 1220 | 4.0mm | 8 ply | 3.20 kg m2 | AB/B |

| 1220 x 1220 | 5.0mm | 10 ply | 4.00 kg m2 | AB/B |

| 1220 x 1220 | 6.0mm | 12 ply | 4.80 kg m2 | AB/B |

| 1550 x 1550 | 1.0mm | 3 ply | 0.80 kg m2 | AB/AB |

| 1550 x 1550 | 1.5mm | 3 ply | 1.20 kg m2 | AB/AB |

| 1550 x 1550 | 2.5mm | 5 ply | 2.00 kg m2 | AB/AB |

This Premium Plywood is used in the manufacture of Model Aircraft, Light Aircraft, Musical Instruments Saddles, Telescopes, Display and Exhibition, Furniture and Souvenirs. GL1 Aircraft grade Plywood is also available with the GL inspection available ex-mill in Finland only. Lead times do apply.

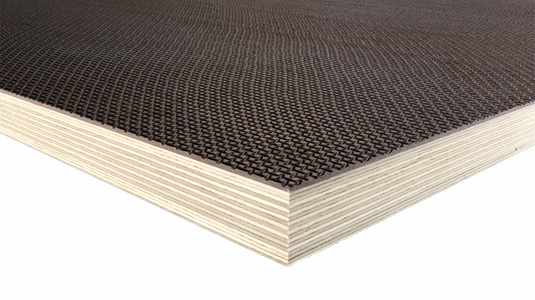

Wisa Wire Slip Resistant Birch Plywood

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1220 x 2440 | 12mm | 9 ply | 8.4 kg m2 | 75 |

| 1220 x 2440 | 18mm | 13 ply | 12.2 kg m2 | 50 |

| 1220 x 2440 | 21mm | 13 ply | 14.3 kg m2 | 30 |

| 1220 x 2440 | 30mm | 13 ply | 20.4 kg m2 | 25 |

WISA-Wire is a plywood panel coated with dark brown phenolic resin coating with slip resistant wire mesh pattern. The product is intended for use as flooring in the transport industry i.e. trailers, railway wagons and building applications such as warehouse floors, loading platforms and scaffolding. WISA-Wire is a universal material for technical flooring applications.

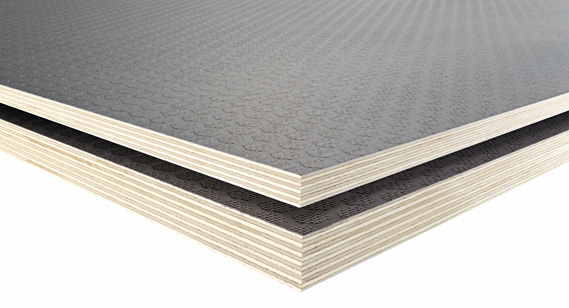

Wisa Hexa Slip Resistant Birch Plywood

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1220 x 2440 | 9mm | 7 ply | 5.9 kg m2 | 100 |

| 1220 x 2440 | 12mm | 9 ply | 6.5 kg m2 | 75 |

| 1220 x 2440 | 18mm | 13 ply | 12.3 kg m2 | 50 |

| 1220 x 2440 | 18mm T&G | 13 ply | 12.3 kg m2 | 50 |

| 1220 x 3050 | 18mm | 13 ply | 12.3 kg m2 | 50 |

| 1800 x 3600 | 18mm | 13 ply | 12.3 kg m2 | 25 |

Wisa Form F22 Exterior Birch Plywood

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1220 x 2440 | 6.5mm | 5 ply | 4.9 kg m2 | 140 |

| 1220 x 2440 | 18mm | 13 ply | 12.5 kg m2 | 50 |

| 1220 x 6000 | 18mm | 13 ply | 12.5 kg m2 | 30 |

WISA-Form Birch core combined with phenolic coating is AS6669 certified. Designed for the formwork end use and has an excellent strength to weight ratio and stable striking properties. Strong standard construction can be optimised further by using strength oriented construction when required.

Wisa Paint Ply Exterior Spruce

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 2440 x 1220 | 12mm | 5 ply | 6.5 kg m2 | 40 |

| 2440 x 1220 | 18mm | 7 ply | 8.9 kg m2 | 25 |

Suitable for painting with 240gsm MDO phenolic finish. Lightweight plywood used on building Facades, Balcony Walls, Eaves, Roof Soffits, Vehicle Doors, Signwriting, Advertising Boards & Playground Structures.

Wisa Paint Ply Exterior Birch

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1220 x 2440 | 15mm | 11 ply | 10.5 kg m2 | 60 |

| 1220 x 2440 | 20mm | 13 ply | 12.5 kg m2 | 50 |

| 1220 x 3050 | 9mm | 7 ply | 6.9 kg m2 | 40 |

| 2440 x 6100 | 9mm | 7 ply | 6.9 kg m2 | 30 |

This premium plywood panel has a paintable coating that will endure ultra-violet rays and is chemical resistant. Main uses for this product are Signs & Billboards, outdoor furniture and garage doors.

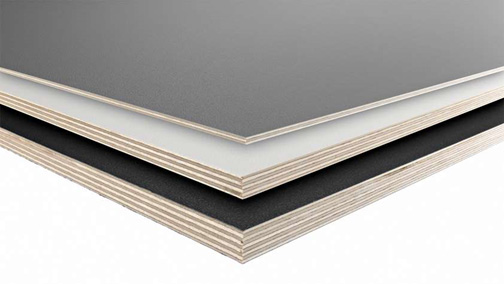

Wisa White Multiwall Exterior Plywood

| Sheet Sizes | Thickness | Ply | Weight | Pack Qty |

|---|---|---|---|---|

| 1525 x 3050 | 6.5mm | 5 ply | 4.8 kg m2 | 40 |

| 1220 x 3050 | 18mm | 13 ply | 12.6 kg m2 | 30 |

Manufactured with a 0.2mm embossed polypropylene coating both sides and has a high resistance to wear. Surface has good chemical resistance (ISO 175) and it is easy to clean with water and detergent. Thanks to its good UV-resistance and color stability (6-7 according to EN ISO 105-B02), product offers long lasting solution for variety of outdoor and indoor use applications which include Vehicle Walls, Horse Trailers,

Shopfitting and Playground Equipment.

Not recommended for a painted application.